Subscribe

Information on new and updated products, upcoming events, and more!

Applications

Secure tubes for mitering

Fix a frame onto a milling table for further machine work

Help prevent tubes from getting damaged

If used for a different application, then the user assumes all risks and no refunds or returns are allowed

Material

Assembly

Consists of two pieces:

One side accommodates two M5 clamping screws (included)

The other side is threaded to accept the clamping screws

Bore

Available in wide variety of sizes:

Choose the correct bore based on the OD of the tube you want to secure

Choose the outside dimensions based on the application you will be using it for

Quantity Discounts

Buy 10+ tube blocks and receive a 10% discount

General Information

Paragon Machine Works took over the supply and manufacturing of Anvil Bike’s dummy axles in October 2019

All Anvil dummy axles are guaranteed to work with the wide variety of Anvil tooling

We do not guarantee that they will work with products manufactured by other companies

Dummy axles that DO have "Exact" in their product title are on-size between faces; for example, a 110 mm dummy axle will measure 110 mm between the faces

Dummy axles that DO NOT have "Exact" in their product title are oversize to help compensate for distortion after welding; for example, a 135 mm dummy axle will measure 137 mm between the faces

Download our Dummy Axle Reference Guide here

Dummy Axles for SRAM UDH/T-Type Dropouts

Flat/Post Mount Dropout with Bolt-on Brake Insert

Flat/Post Mount Dropout with Bolt-on Brake Insert

Dropout Part Numbers: DR1103 (stainless steel)

Parts needed for dummy axle assembly:

Flat Mount Dropout for 160/180 mm Rotor

Flat Mount Dropout for 160/180 mm Rotor

Dropout Part Numbers: DR2102 (steel, no eyelets), DR2104 (steel, with eyelets)

Parts needed for dummy axle assembly:

OR purchase:

Round, Rear Dropout with Integrated Brake Mount

Round, Rear Dropout with Integrated Brake Mount

Dropout Part Numbers:

Parts needed for dummy axle assembly:

OR purchase only:

Round, Rear Dropout

Round, Rear Dropout

Dropout Part Numbers:

Parts needed for dummy axle assembly:

OR purchase only:

Conventional Sliding Dropout Inserts

Conventional Sliding Dropout Inserts

Insert Part Numbers: DR4145 (right side), DR4146 (left side)

Rocker Dropout

Rocker Dropout

Insert Part Number: DR4147 (right side)

Parts needed for dummy axle assembly:

OR purchase only:

Dummy Axles for 10 mm Rear Dropouts

Indexes (fixes) the dropout using the hub recess on the dropouts

1" (25.4 mm)

Other tools that use a 1/2" OD x 2-1/2" long center section dummy axle

Dummy Axles for 12 mm Rear Dropouts

Choose your dummy axle based on the dropout that you will be using

Indexes (fixes) the dropout using the hub recess on the dropouts

1" (25.4 mm)

Allows the dropout to rotate around the center of the axle

Dummy Axles for 9 mm Front Dropouts

Choose your dummy axle based on the dropout that you will be using

Indexes (fixes) the dropout using the hub recess on the dropouts

Allows the dropout to rotate around the center of the axle

OD: 3/4" (19 mm)

Tooling Compatibility:

Dummy Axles for 12 mm Front Dropouts

Choose your dummy axle based on the dropout that you will be using

Indexes (fixes) the dropout using the hub recess on the dropouts

Allows the dropout to rotate around the center of the axle

Dummy Axles for 15 mm Front Dropouts

Choose your dummy axle based on the dropout that you will be using

Indexes (fixes) the dropout using the hub recess on the dropouts

Allows the dropout to rotate around the center of the axle

General Information

Introduces argon into the frame

Absorbs heat from the weld to reduce distortion

Distortion will not be completely eliminated

Results will vary based on tubing diameters, wall thicknesses, and personal welding styles

In our shop tests, we were able to install a threaded bottom bracket assembly with no post-weld machining

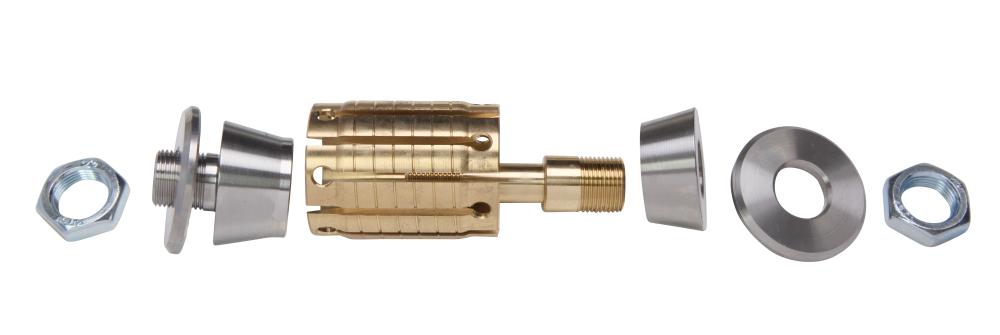

Assembly Components

All metal-to-metal interfaces are bronze to stainless steel

Center: 1 each

Cones: 1 each threaded and unthreaded

Thru Bolt: 1 each

Washers: 2 each

Hex Nuts: 2 each

Steps for Use

1) After the frame has been tacked, remove from the fixture

2) Insert the bronze expanding sleeve into the bottom bracket shell

3) The sleeve must be compressed slightly to get it in the shell

4) Place both cones in the sleeve

5) Insert bronze draw bolt through one cone and thread it into the cone on the opposite side

6) Using the 8 mm internal hexagon in the bolt, tighten the bolt which will expand the sleeve

7) Install both washers

8) Install mating nuts

Applications:

Material: 1018 steel

OD: 3/4"

Lengths: 2-1/2" and 7-1/4"

Available Threads: